Rebar Couplers

Rebar Couplers Specification

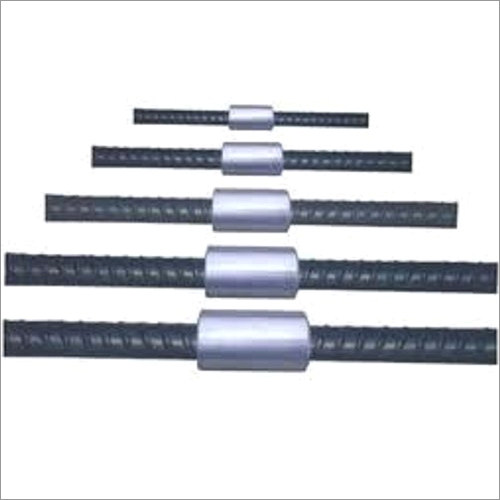

- Usage

- Joining Reinforcement Bars

- Application

- Construction, Civil Engineering, Structural Connections

- Size

- Standard (12mm to 40mm Diameter)

- Weight

- Depends on Size (Approx. 0.2kg - 2kg)

- Color

- Black, Grey

- Tensile Strength

- Up to 700 MPa

- Capacity

- Designed to Exceed Bar Strength

- Feature

- High Strength, Easy Installation, Corrosion Resistance

Rebar Couplers Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 4 Days

- Main Domestic Market

- Odisha, West Bengal, Jharkhand

About Rebar Couplers

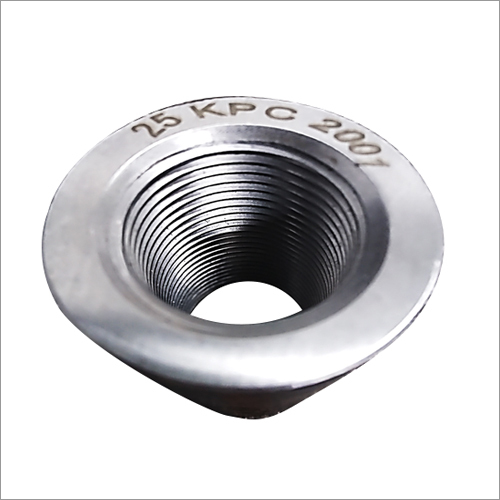

Rebar Couplers are mainly used for joining rebars with full tension capacity. The ends of bars to be joined are provided with threads and are joined using a coupler sleeve that transfers the force on the rebar across the connection. Rebar Couplers is a that is used to connect two shafts together at their for the purpose of transmitting power. The primary use of coupling is to join two pieces of rotating equipment that permits some degree of misalignment or end movement or both.

Product details

|

Surface Type |

Color Galvanized |

|

Material |

EN-8D |

|

Model Name/Number |

KPC Make |

|

Coupler Type |

Rebar Coupler |

|

Size |

12mm to 40mm |

|

Usage/Application |

Construction |

|

Dimension |

12mm to 40mm |

Superior Mechanical Splicing Solution

Designed for seamless and robust connection of rebar, these couplers employ parallel or tapered threads and provide unmatched performance for structural integrity. Their high-grade build and anti-rust coating ensure resistance to harsh environmental conditions, making them a preferred choice for professional construction projects.

Long-Term Reliability and Protection

With a temperature range spanning from -20C to +80C, the rebar couplers cater to varied installation climates. Their weather-resistant and corrosion-protected design, featuring a painted finish, guarantees extended durability and dependable service life, even under challenging conditions encountered in infrastructure development.

FAQs of Rebar Couplers:

Q: How are rebar couplers with parallel or tapered threads installed?

A: Rebar couplers are installed by manually or mechanically tightening the cylindrical device onto the threaded ends of the reinforcement bars. This process creates a firm mechanical splice, eliminating the need for welding or additional adhesives.Q: What benefits do anti-rust coated rebar couplers provide in construction projects?

A: The anti-rust coating offers superior corrosion protection, significantly enhancing the durability and longevity of the spliced bars. This ensures the structural stability and reduces maintenance costs over time.Q: When should mechanical splice rebar couplers be selected over traditional coupling methods?

A: Mechanical splice rebar couplers should be chosen when projects demand high shear strength performance, quick installation, improved safety, and minimal downtime, especially in temperature ranges from -20C to +80C.Q: Where are these rebar couplers manufactured and exported from?

A: These rebar couplers are produced and exported by manufacturers and suppliers based in India, serving both domestic and international construction markets with quality-assured products.Q: What is the process for ensuring the weather resistance and surface durability of these couplers?

A: The process includes applying a painted surface treatment and an anti-rust coating, which together shield the coupler from moisture, chemicals, and environmental wear, thereby securing its long-term performance.Q: How does the cylindrical shape of the coupler impact its usage?

A: The cylindrical form allows uniform tightening and load distribution along the bar splice, providing reliable connection and enhanced mechanical performance in structural applications.Q: What material options are available for these rebar couplers?

A: Rebar couplers are manufactured using a variety of high-strength materials tailored for structural applications, ensuring compatibility and resilience in demanding construction settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+